WITH SELF-ADJUSTING CLAMPING RANGE HIGHLY FLEXIBLE AND UP TO 5 TIMES FASTER CLAMPING

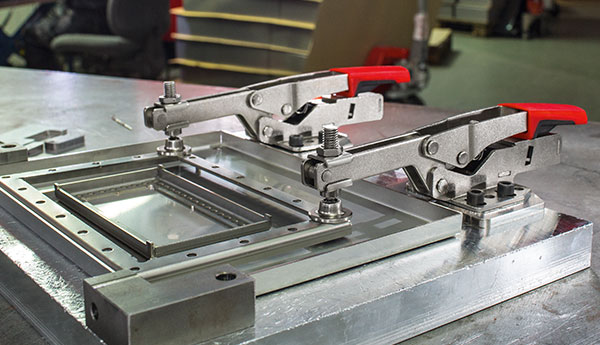

The variable BESSEY STC toggle clamps combine innovative technology with the highest BESSEY quality. The result: BESSEY toggle clamps have an extremely large clamping range and adapt automatically to different work piece dimensions within a certain clamping range. The benefits are clear to see:

One size of the BESSEY toggle clamp replaces multiple competitor sizes simultaneously and it can be used up to 5 times faster.

THE ADVANTAGES OF BESSEY TOGGLE CLAMPS

"BESSEY. Simply better." – a challenge BESSEY sought to rise to, even when looking for options to expand its range. This involved an extensive analysis of clamping tools related to the current product portfolio. The toggle clamp segment came more and more to the forefront as it is a segment containing products that have not undergone much innovation in years. In its development, BESSEY pursued one objective: "Innovate – don’t imitate". The most significant disadvantages of traditional toggle clamps – time-consuming adjustment of the clamping range and lack of options to vary the clamping force – needed to be eradicated. But how? By transferring the screw clamp principle of quick adjustment to different work piece dimensions, to BESSEY toggle clamps.

Uncompromisingly versatile

One size of the BESSEY toggle clamp replaces multiple competitor sizes simultaneously:

- due to an extremely large clamping range, thanks to the patented mechanism

Ready to go

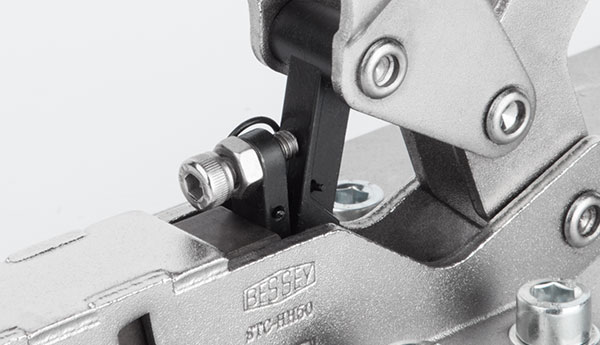

BESSEY STC toggle clamps adapt to workpieces of varying thickness – without manual setting of the spindle and, with practically the same clamping force:

- due to an automatic clamping width range

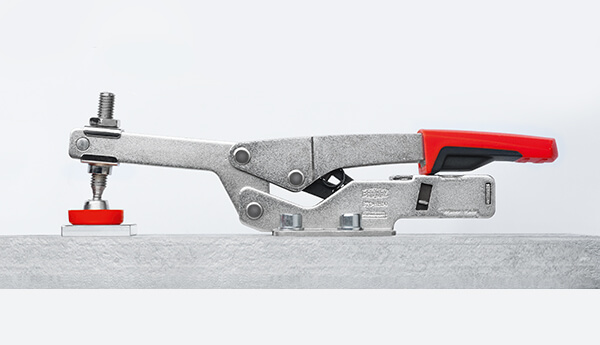

Powerful and gentle

Even sensitive workpieces, e. g. with veneered or varnished surfaces, can be gently clamped:

- due to moving pressure plate with removable protective cap

- due to clamping force regulation via adjustment screw in the joint

WHICH TOGGLE CLAMP IS USED WHEN?

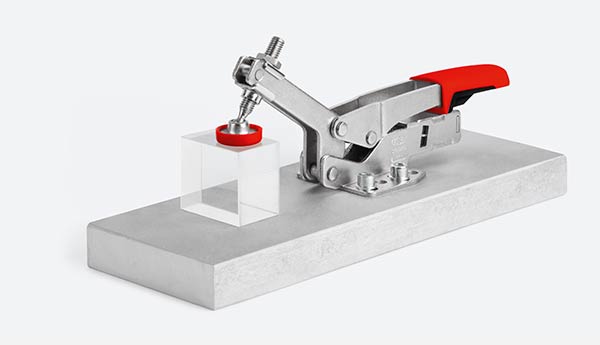

Horizontal toggle clamps

The horizontal toggle clamp is a perfect fixing option for work pieces, when a handle would get in the way while working. Here, the work piece is fixed quickly from above, with the handle being pressed down from above. In the clamped position, the handle remains parallel to the contact surface, allowing more secure working of the work piece.

The variable horizontal clamp is available with three base plate versions and with clamping ranges of 35, 40 and 60 mm.

Vertical toggle clamps

With the vertical toggle clamp, the work piece is fixed from above, as with the horizontal clamp. In this case, however the lever is moved from bottom to top to clamp, and remains in the clamped position vertical to the table. This can be particularly advantageous when working on hard-to-access areas or when working opposite the clamping device.

The variable vertical clamps are available with a horizontal base plate and with clamping ranges of 35 and 40 mm.

Inline toggle clamps

The inline toggle clamps have proven particularly practical when carrying out milling and drilling work. The movement of the lever is converted into axial movement of the push rod, which means that the work piece is fixed from the side, rather than from above.

The inline toggle clamp is available with two base plate versions and with clamping ranges of 25 and 35 mm.

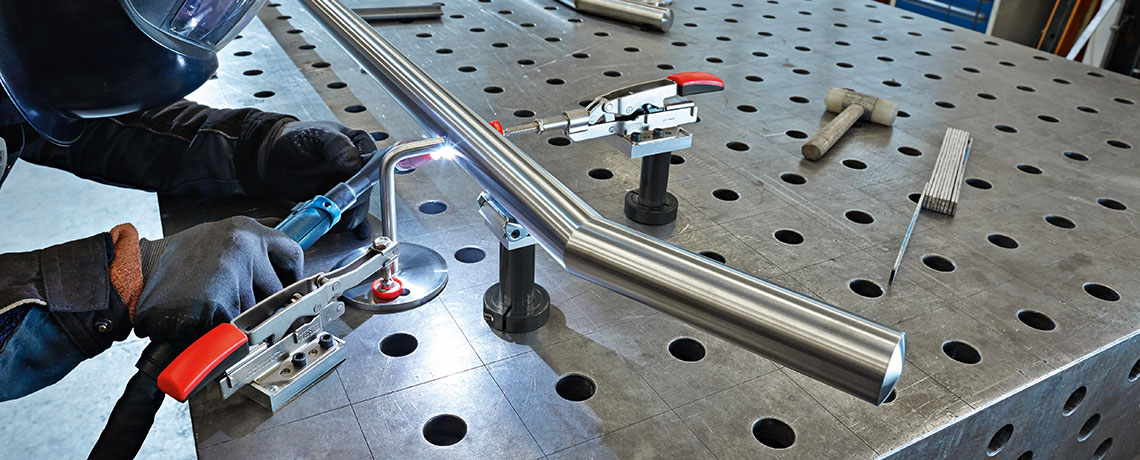

USE ON WELDING TABLES

For the use on welding tables with 16 mm and 28 mm hole diameters

The welding table clamp adapter is suitable for use directly in the hole pattern of the welding table.

It can also be attached to the appropriate welding table clamp extension without the need for bolts. The adjusting ring can be used to lower the round material in the table with infinite adjustment. Combined in this way, the toggle clamp can also be positioned over the table, on the work piece.

USE ON MULTIFUNCTION TABLES

For the use with 20 mm hole diameter and 19 to 25 mm plate thickness (e.g. Festool MFT or Sortimo WorkMo)

The workbench adapter allows BESSEY toggle clamps to be used on multifunction tables. The three-part accessory set can be assembled in a few simple steps. For this, a locking pin is attached via a cylinder screw under the base plate. Added in this way, the toggle clamp can be used directly in the multifunction table and secured from underneath with a knurled nut.